We strive to always grow and better ourselves to be unique, manufacturing parts with a high degree of accuracy suiting our Customers’ specific needs and requirements.

We want to be your destination.

If you need it, we can make it.

If you need it,

we can make it.

3000

sqm

25

employees

9001

iso

2.5 M€

turnover

LMB operates since 1968.

Technologies, materials and design change the shape of our world every day, moving it forward.

Our

Products

LMB is a built-to-print mechanical company offering a series of co-design, prototyping, one-shot production, short series activities and serial production in different application fields.

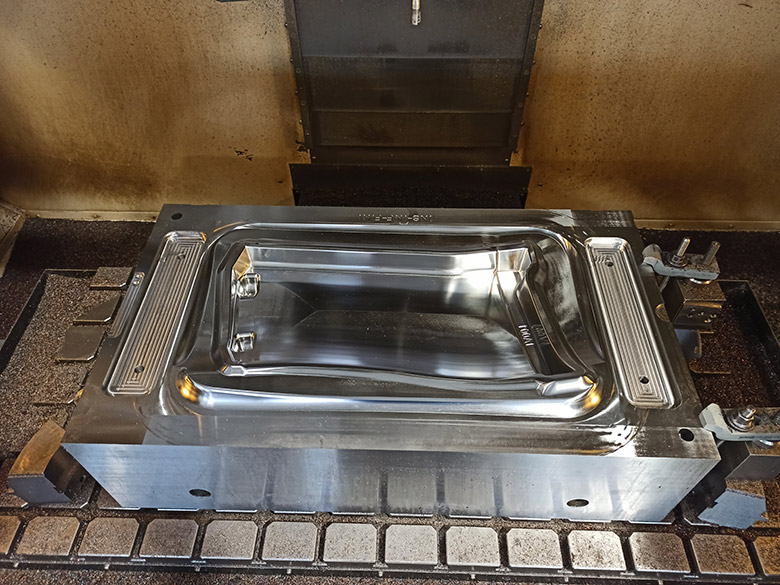

MOLDS

Molds for sheet metal, plastic and rubber in standard or special steels, and possibly specifically coated if needed, including with highly abrasion resistant polyurethan.

ROLLERS

Rollers tools for Pipe Manufacturers in top-quality special highly wear steels.

AERO TECH

Tools and prototype parts used by Aerospace manufacturing companies.

INDUSTRIAL

Hundreds of different mechanical parts used in many different fields and by numerous customers worldwide.

MISSION

We produce components with a high degree of precision for many different industries, with passion, expertise and experience.

Our focus is on Customers’ needs and responsibility, transparency, creativity, flexibility, technological advancement and productive process advancements, as well as competence, competitiveness and continuous training are the values we follow since our establishment in 1968.

Over the years our company has become technologically advanced and highly qualified thanks to craftsmanship-oriented entrepreneurship, making flexibility and care for Customer’s needs our key strength.

We follow the entire manufacturing process, working side by side with the Customer and providing support throughout manufacturing; from supplying raw materials with precise specifications to producing products meeting high precision standards, we constantly check our products to meet all requirements, manage external operations such as heat or surface treatments to give our Customers a complete finished product.

We recently moved forward on a modern and flexible organization, a working ERP system, a safe and healthy working environment and a series of opportunities for learning and constant professional growth.

REFERENCES